News

Mission accomplished for the installation of the first main span segment of the cable-stayed bridge

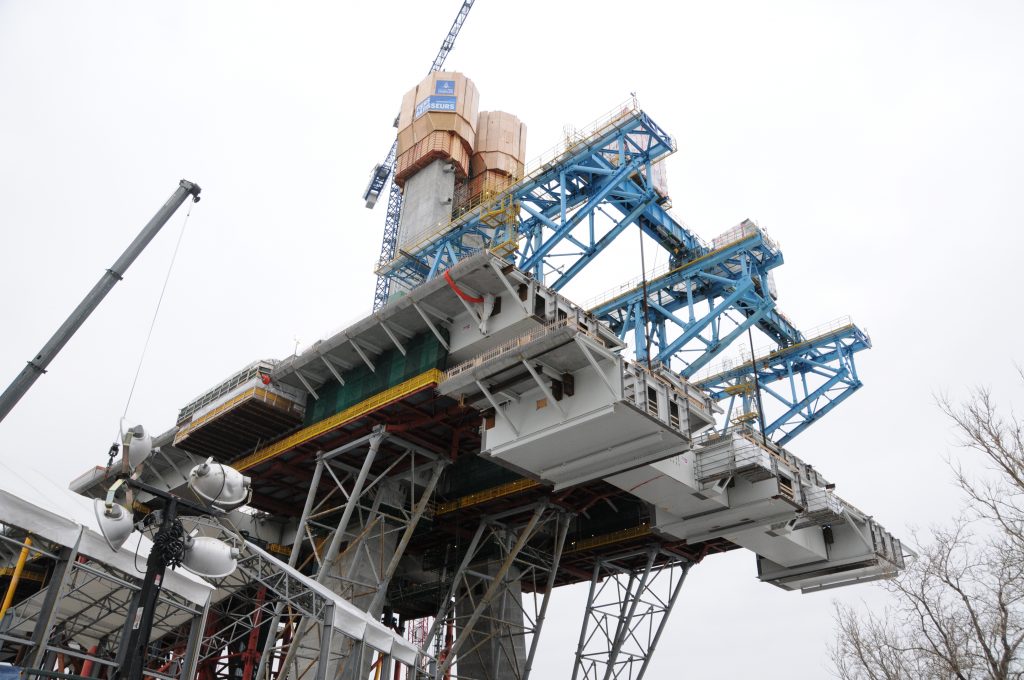

At the end of March, the teams for the cable-stayed portion executed a vital and highly complex manoeuvre with the installation of the first main span segment over the Saint Lawrence Seaway.

Frédéric Guitard, Area Manager for the cable-stayed portion, expresses his pride: “It is a singular moment for all of the project teams since, given their size of 60 metres wide by 12.5 metres long and weight of 850 metric tons, the 15 main span segments will be among the largest ever installed in the world on a structure of this scale,“

Installation of the main span segments : the main steps

The typical cycle of installation expected to take up to 3 weeks, following precasting on the jetty and at the foot of the main pylon. Here are the 4 key steps:

- Step 1: The “moveable lifting beams (MLB)” raise the main span segment from the ground to the lower part of the bridge’s superstructure, where the load is transferred to two “trolleys”.

- Step 2: Operating in tandem, the two rack & pinion self-propelled trolleys travel along a cog rail using to bring the bridge section to the tip of the main span cantilevered deck;

- Step 3: The “Dynamic Lifting Frame and Upper Crossbeams” set up at the tip of the main span cantilever then takes over the load of the segment, positioning the main span segment so it can be bolted in place; and

- Step 4: Once cable stays are added to finish the installation of the main span segment, the final concreting of the deck slabs completes the superstructure.

Rising to the challenge

One of the factors that make installing the main span such a complex process is that Seaway traffic cannot be disrupted during work on the cable-stayed bridge. We must therefore install these gigantic bridge segments over the marine highway, without interfering with the flow of commercial ships.

Antonio Caracena, in charge of the superstructure of the cable-stayed portion, admits that work on the main span is one of the most difficult challenges of the project: “We have been planning these operations for over two years because of the extreme level of precision required. In terms of detail, it’s comparable to making a Swiss watch, only with parts weighing several hundreds of tons, held up 50 metres in the air by two cables. The first operation went smoothly. We went slowly and cautiously, since it was the first.“

The first hoisting was the result of continuous, 24/7 efforts by our teams in design and construction on-site, in the United States, in Spain, in Switzerland and in Italy, and by our proud workers here in Quebec. It was truly an international effort.

Main span: 15 segments to be installed

12 main span segments will be installed in the upcoming months over the Saint Lawrence Seaway to reach the other three, which will start at Île‑de‑la‑Couvée, on the South Shore side.

Main span segment by the numbers

- Width: 60 metres

- Length: 12.5 metres

- Average weight: 850 metric tons

- Number of main span segments to be installed: 15